Mastering the Art of Metal Fusion: A Comprehensive Guide to Jewelry Soldering Kits

Related Articles: Mastering the Art of Metal Fusion: A Comprehensive Guide to Jewelry Soldering Kits

Introduction

With great pleasure, we will explore the intriguing topic related to Mastering the Art of Metal Fusion: A Comprehensive Guide to Jewelry Soldering Kits. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Mastering the Art of Metal Fusion: A Comprehensive Guide to Jewelry Soldering Kits

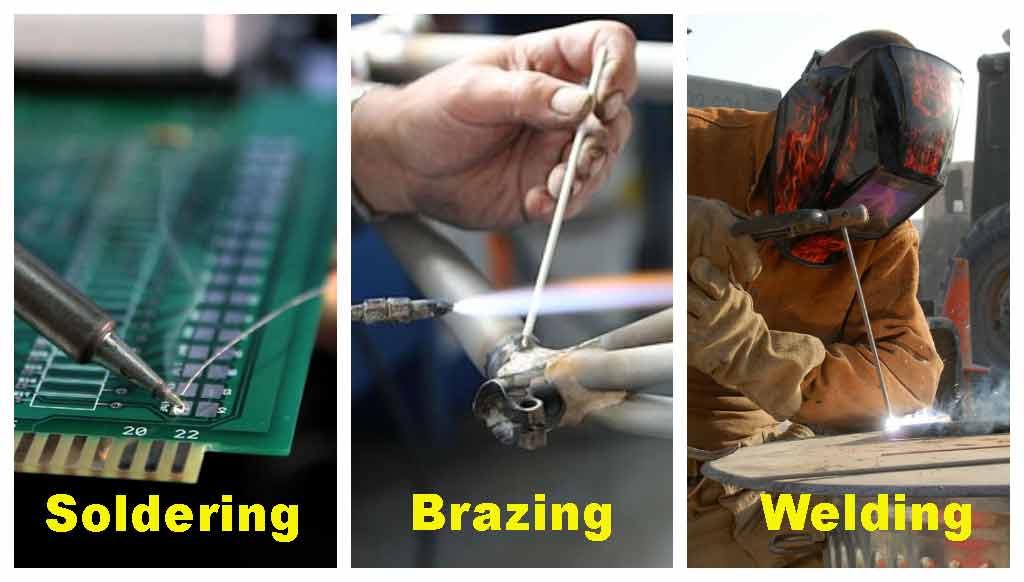

The world of jewelry crafting is a captivating blend of artistry and technical skill. One of the essential techniques in this realm is soldering, the process of permanently joining two pieces of metal using a filler metal with a lower melting point. For aspiring and seasoned jewelers alike, a dedicated soldering kit provides the tools and materials necessary to execute this critical step with precision and confidence.

This guide delves into the intricacies of jewelry soldering kits, offering a comprehensive understanding of their components, applications, and the crucial role they play in the jewelry-making process.

Understanding the Essentials: Components of a Jewelry Soldering Kit

A well-equipped jewelry soldering kit is an investment in quality and convenience, offering a curated selection of tools and materials tailored to the specific demands of jewelry fabrication. Typically, a comprehensive kit will include:

-

Soldering Torch: This is the heart of the soldering process, providing the concentrated heat needed to melt the solder and fuse the metal pieces. Common types include propane torches, butane torches, and oxy-acetylene torches, each offering distinct advantages in terms of heat intensity, flame control, and portability.

-

Solder: The crucial element that binds the metal pieces together. Solder is an alloy composed primarily of silver, gold, or copper, with specific melting points tailored to different metals and applications. Common solder types include:

- Hard Solder: Higher melting point, used for structural joins and applications requiring greater strength.

- Medium Solder: Offers a balance between strength and ease of use, suitable for general jewelry construction.

- Easy Solder: Low melting point, ideal for delicate work and repairs.

-

Flux: A chemical compound essential for successful soldering. Flux acts as a cleaning agent, removing oxides from the metal surfaces, ensuring a clean and strong bond. Different flux types are formulated for specific metals and soldering temperatures.

-

Soldering Block: Provides a stable and heat-resistant platform for holding the pieces being soldered. Soldering blocks are often made of firebrick or ceramic, offering excellent thermal conductivity and resistance to high temperatures.

-

Safety Gear: Essential for protecting the user from potential hazards associated with soldering. This includes:

- Safety Glasses: Shield the eyes from sparks and debris.

- Gloves: Protect hands from heat and potential burns.

- Apron: Protects clothing from accidental spills or splashes.

-

Additional Tools: Kits may include a variety of additional tools, depending on their intended use. Common additions include:

- Tweezers: For manipulating small pieces during the soldering process.

- Pliers: For holding and manipulating larger pieces.

- Sandpaper: For cleaning and preparing metal surfaces before soldering.

- Cleaning Solutions: For removing flux residue after soldering.

The Art of Soldering: A Detailed Look at the Process

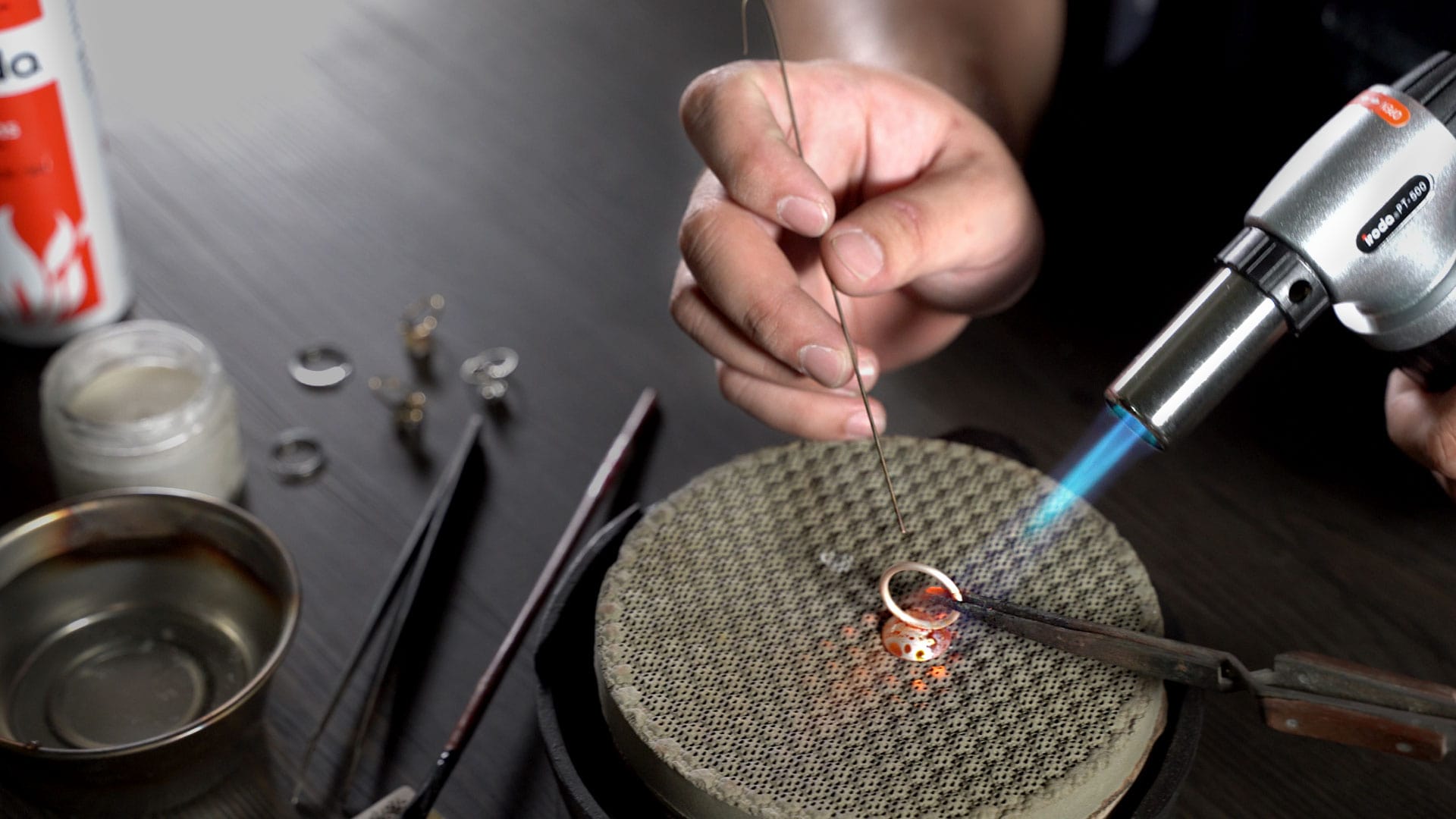

Soldering is a precise and meticulous process that demands both technical skill and artistic finesse. The following steps outline the fundamental principles of soldering jewelry:

-

Preparation: Begin by thoroughly cleaning the metal surfaces to be soldered. This involves removing any dirt, grease, or oxidation using a suitable cleaning solution or sandpaper.

-

Flux Application: Apply a thin layer of flux to the surfaces to be joined. Flux acts as a cleaning agent, removing oxides and promoting a strong bond.

-

Positioning: Secure the pieces to be soldered in the desired position on the soldering block. Ensure a secure and stable arrangement to prevent movement during the heating process.

-

Heating: Use the soldering torch to heat the metal pieces and the solder simultaneously. Focus the flame on the joint area, ensuring even heat distribution.

-

Solder Application: Once the metal reaches the solder’s melting point, carefully apply the solder to the joint. The solder will flow into the joint, creating a strong and permanent bond.

-

Cooling: Allow the soldered piece to cool slowly and naturally. Avoid quenching in water, as this can cause stress and potential cracking.

-

Cleaning: After cooling, clean the soldered piece thoroughly to remove any flux residue. This can be done using a suitable cleaning solution or by gently scrubbing with a brush.

Benefits of Utilizing a Jewelry Soldering Kit

Investing in a dedicated soldering kit offers numerous advantages for jewelry makers:

-

Enhanced Precision: The tools and materials included in a kit are specifically designed for jewelry soldering, enabling greater precision and control over the process.

-

Safety First: The inclusion of safety gear ensures that the user is adequately protected from potential hazards associated with soldering.

-

Convenience: A kit provides all the necessary components in one convenient package, eliminating the need to purchase individual items separately.

-

Versatility: Kits often include a variety of solder types, allowing for different applications and melting points, catering to diverse jewelry projects.

-

Quality Assurance: Reputable soldering kits feature high-quality tools and materials, ensuring reliable and consistent results.

Choosing the Right Kit for Your Needs

Selecting the appropriate soldering kit requires considering the following factors:

-

Skill Level: Beginners may benefit from a basic kit with essential tools and materials, while experienced jewelers may opt for a more comprehensive kit with specialized tools.

-

Project Scope: The intended projects will influence the choice of solder types and tools.

-

Budget: Kits come in a range of price points, catering to various budgets.

-

Brand Reputation: Choosing a kit from a reputable brand ensures quality and reliability.

FAQs: Addressing Common Queries Regarding Jewelry Soldering Kits

Q: What is the difference between hard, medium, and easy solder?

A: Solder types are classified based on their melting points. Hard solder has the highest melting point, followed by medium solder, and then easy solder. The choice of solder depends on the strength required for the joint and the type of metal being soldered.

Q: How do I choose the right flux for my soldering project?

A: Flux is chosen based on the type of metal being soldered and the soldering temperature. Different flux types are formulated to remove oxides from specific metals and work effectively at different temperatures.

Q: What safety precautions should I take when using a soldering kit?

A: Always wear safety glasses, gloves, and an apron when soldering. Work in a well-ventilated area, and avoid inhaling fumes. Keep flammable materials away from the soldering area.

Q: How do I prevent solder from flowing where I don’t want it to?

A: Use a heat sink to prevent heat from spreading to unwanted areas. A heat sink is a material that absorbs heat, like a wet cloth or a piece of steel.

Q: How do I clean flux residue after soldering?

A: Use a suitable cleaning solution or a brush to remove flux residue. Avoid using abrasive cleaners that can damage the metal surface.

Tips for Success: Optimizing Your Jewelry Soldering Experience

-

Practice Makes Perfect: Soldering is a skill that requires practice and patience. Start with simple projects and gradually work your way up to more complex pieces.

-

Invest in Quality Tools: Using high-quality tools and materials is essential for achieving consistent results.

-

Maintain Cleanliness: Keep your workspace and tools clean to prevent contamination and ensure optimal soldering conditions.

-

Work in a Well-Ventilated Area: Soldering produces fumes that can be harmful if inhaled. Always work in a well-ventilated area.

-

Seek Guidance: If you are new to soldering, consider taking a class or seeking guidance from an experienced jeweler.

Conclusion: Embracing the Mastery of Metal Fusion

A jewelry soldering kit empowers aspiring and seasoned jewelers alike to master the art of metal fusion. By providing the essential tools and materials, these kits facilitate precision, safety, and versatility in the jewelry-making process. With proper knowledge, practice, and adherence to safety guidelines, soldering becomes a rewarding and integral part of creating beautiful and enduring jewelry pieces. As you embark on your journey of jewelry crafting, a dedicated soldering kit will serve as a valuable companion, supporting your creative endeavors and enabling you to bring your artistic visions to life.

Closure

Thus, we hope this article has provided valuable insights into Mastering the Art of Metal Fusion: A Comprehensive Guide to Jewelry Soldering Kits. We thank you for taking the time to read this article. See you in our next article!